FOR AREAS WHERE ENHANCED DURABILITY AND CUSTOM BEAUTIFICATION ARE REQUIRED

FOR AREAS WHERE ENHANCED DURABILITY AND CUSTOM BEAUTIFICATION ARE REQUIRED

Flake Floor Systems are decorative, textured, epoxy-based floor surfacing systems designed to provide an attractive, slip resistant, and clean-able surface for light traffic areas. Flake Floor Systems are durable and chemical resistant, making them ideal for resurfacing concrete floors in research facilities, correctional institutions, hospitals and healthcare facilities, education facilities, and a wide variety of light manufacturing areas. After mixing and application, Flake Floor Systems cure to a dense, impervious surface.

Epoxy products are designed for use by the specialty concrete flooring professional. All epoxies, coatings, and other concrete flooring formulas incorporate advanced chemistry to deliver high-quality flooring appearance and durability.

ADVANTAGES AND BENEFITS

Durable: Epoxy flooring systems provide superior chemical and abrasion resistance over pre-engineered floors.

Durable: Epoxy flooring systems provide superior chemical and abrasion resistance over pre-engineered floors.- Decorative: Enhance your high-performance flooring environment by adding custom color and texture to compliment any décor.

- Economical: Flake resinous flooring systems provide a cost-effective alternative to pre-engineered floors.

- Safe: Flake epoxy flooring media provides an orange-peel texture that increases the slip-resistance and safety.

- Clean: Resinous flooring systems are wax free and economical to upkeep with soap and water.

- Monolithic: Epoxy flooring provides a seamless floor of wall-to-wall beauty that does not collect dirt, moisture, or germs.

- Low Sound: Resinous flooring systems can be design engineered to provide a seamless and flexible surface that deadens the noise of foot traffic and carts.

- Renewable: After years of use, efficiently revitalize your epoxy flooring system by sanding the surface and applying a new topcoat.

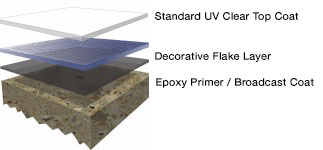

APPLICATION LAYERS

OPTIONAL TOPCOATS

Why Are Optional Topcoats Beneficial?

- Additional scratch and mar resistance

- Additional UV resistance to help colors look their best and resist fading/yellowing over time

- Hot tire resistance – excellent for garages, warehouses, and other facilities where vehicles travel

- Easy-to-clean surface for wiping up spills or sweeping debris

Optional Topcoats

Two-component polyaspartic aliphatic polyurea utilizing innovative proprietary nanotechnology. It provides a high-gloss clear coating. Its extremely quick curing time provides unmatched labor-saving capabilities over epoxies and polyurethanes.

High-solids, gloss finish, two-component, water-based aliphatic polyurethane. This high-performance material has excellent hardness, abrasion resistance, hot tire resistance, chemical resistance, low VOC, and low odor with multiple uses.

Required System Components

Superior low-viscosity 2-component, 100% solid clear aliphatic epoxy. Provides excellent abrasion resistance and longlasting protection, has good resistance to most common chemicals, and meets all USDA guidelines for use in federally inspected facilities. Also provides excellent UV protection, scratch resistance, and gloss retention.

Flake Blends are composed of vinyl-based chips of unlimited colors.

An economical 2-component, 100% solids epoxy body/basecoat material for heavy-duty flooring systems. Is a VOCcompliant material that meets all of the USDA guidelines for use in federally inspected facilities. Can be field pigmented with colorants.

Click on graphic to see enlarged options.

Click on graphic to see enlarged options.